Sydney’s built environment carries the legacy of an era when asbestos was widely used in homes, factories, schools, and public facilities. Before redevelopment or new construction can begin, many of these sites require asbestos remediation — the careful identification, removal, and disposal of hazardous materials. Done properly, this process protects workers, communities, and future occupants, while ensuring projects can move forward without delays.

At WBS Engineers, asbestos remediation is our core expertise. We hold a Class A license, which allows us to manage both friable and non-friable asbestos across NSW. Backed by ISO-certified systems and experienced teams, we deliver safe, compliant solutions on projects of every scale.

What Is Asbestos Remediation?

Asbestos remediation is the process of safely removing and disposing of asbestos-containing materials (ACMs). When disturbed, asbestos fibres can become airborne and cause serious health conditions, which is why removal in NSW is highly regulated and restricted to licensed contractors.

The Process of Asbestos Remediation

1. Identification and Site Assessment

- A site assessment is carried out, followed by a soil characterisation report.

- Based on this report, waste analysis and classification are performed to detect ACMs.

- A Remediation Action Plan (RAP) is then prepared, outlining feasible remediation options for the site.

- From the RAP, an Asbestos Remediation Control Plan (ARCP) is developed, which details the safe removal strategy.

2. Remediation Options

Depending on the site and level of contamination, solutions may include:

- On-site treatment to destroy or neutralise contaminants.

- Off-site treatment at approved facilities.

- Consolidation and containment within engineered barriers.

- Removal and replacement, where contaminated soil is taken to licensed facilities and replaced with clean fill.

3. Pre-Works Documentation

Before remediation begins, key preparatory steps ensure compliance and safety:

- Dial Before You Dig (DBYD) to map existing underground utilities.

- Services search and marking to protect live assets.

- Community notification letters where residential areas are affected.

- Safework NSW notifications lodged prior to mobilisation.

- Preparation of Asbestos Remediation Control Plan (ARCP), Asbestos Management Plan (AMP), and Safe Work Method Statement (SWMS) to outline procedures and risk controls.

Worker Safety and Site Protocols

1. Personal Protective Equipment (PPE)

The type of asbestos determines PPE requirements. For friable asbestos, minimum controls include:

- P3 full-face respirators

- Disposable coveralls and gloves

- Eye protection

- Safety boots with disposable covers

2. Worker Training and Compliance

All asbestos personnel undergo:

- Fit testing for respirators

- Medical clearance

- Competency training

3. Site Establishment Protocols

- Licensed Asbestos Assessors (LAA) and hygienists supervise all works.

- Exclusion zones are created with fencing and geotextile barriers.

- Decontamination units and site facilities are installed before work begins.

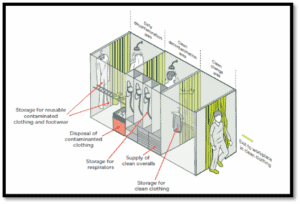

The Decontamination Process

1. Personnel Decontamination

- Dry units used for bonded (non-friable) asbestos.

- Wet units with showers are mandatory for friable asbestos. These include three stages:

- Contaminated gear removed.

- Shower and detergent wash.

- Clean area for fresh clothing.

2. Machinery Decontamination

- Excavators, trucks, and loaders are cleaned at designated wash-down zones.

- Air filters are replaced and machinery is inspected by an LAA.

- Certification is issued once equipment is deemed clear of contamination.

Post-Remediation and Compliance

Air Monitoring

Independent air monitoring ensures fibre levels remain below safe thresholds.

Clearance Certificates

An LAA issues clearance once the site passes inspections and monitoring. This legal document confirms the area is safe for occupation or redevelopment.

Long-Term Environmental Management Plans (LTEMP)

For sites where complete removal is not possible, an LTEMP provides a framework for ongoing monitoring and risk management. This may include groundwater testing, restricted land use, or periodic inspections.

Why It Matters

Much of Sydney’s infrastructure predates the asbestos ban, meaning hazardous materials are still present in many buildings. If not managed correctly, asbestos can halt approvals, delay construction, and — most importantly — endanger workers and the public.

Handled early and by the right contractor, remediation protects people, secures compliance, and keeps projects on track.

How WBS Engineers Delivers

At WBS Engineers, we specialise exclusively in asbestos remediation. Every system, resource, and training program is designed with this focus. Our Class A license enables us to handle both friable and bonded asbestos with the highest safety standards.

A recent example is the Auburn Park Extension, where our team conducted asbestos removal in a live community environment. The project was completed with minimal disruption, demonstrating our ability to balance safety, compliance, and stakeholder needs.

Why Clients Choose Us

- Licensed for friable and non-friable asbestos removal

- End-to-end solutions, from testing to clearance certification

- Experienced with live, high-risk, and community settings

- ISO-certified management systems (ISO 9001, 14001, 45001)

- Transparent communication and detailed reporting

Final Word

Asbestos remediation is not just about ticking a compliance box. It is about protecting people, safeguarding the environment, and setting projects up for long-term success.

With licensed expertise, proven systems, and a track record across NSW, WBS Engineers ensures every site we remediate is safe, compliant, and ready for its next chapter.